Weld backing tape manufacturer in mumbai chennai bangalore and pune get details of fiberglass tape ceramic backing tape ceramic backing strip fiber weld backing tape aluminium backing tape products.

Ceramic weld backing strips.

Esab refrac t back 1 4 x 1 x 1 non metallic ceramic 215r weld backing.

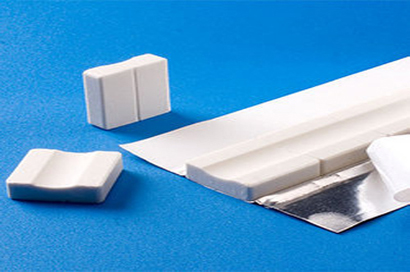

The strips are available in a range of configurations for differing applications and resulting weld bead shapes.

And our welding ceramic backing has very smooth finish color uniformity and makes one side welding both sides beads shaped in fine quality.

Our ceramic weld backing offers complete joint penetration and adhesion.

The strips are available in a range of configurations for differing applications and are supplied in box quantities cut to 60cm strips.

Our backing can support a variety of welding ceramic welding jobs as.

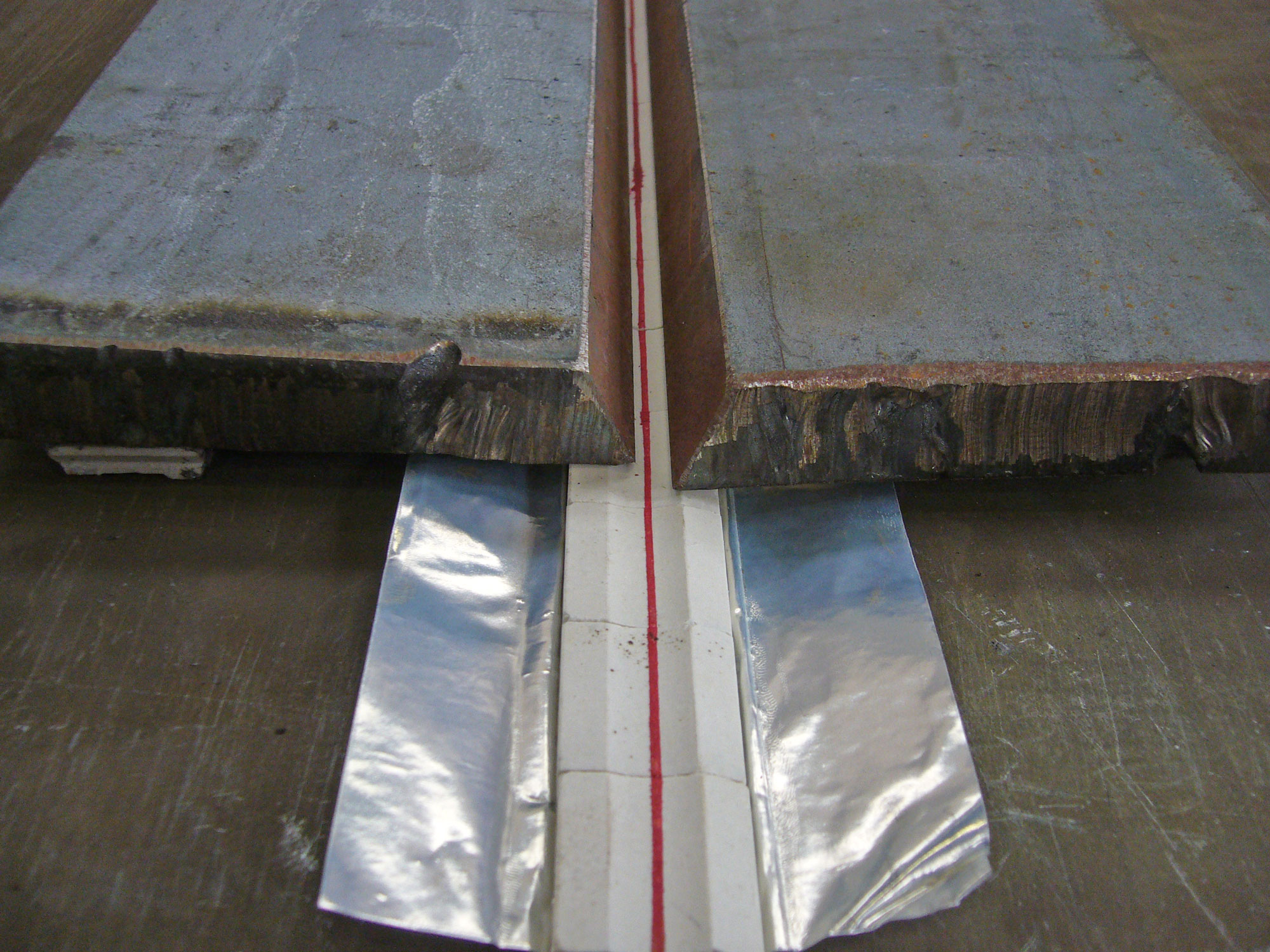

Ceramic tiles usually are held on an adhesive tape that can be affixed to the backside of the weld.

A backing strip may be used on butt joints tee joints and outside corner joints.

The use of ceramic backing strips enables welding to be carried out from a single side with full penetration and reduces and often removes the need to grind out and re weld a root from the reverse side.

It is inexpensive easily applied and requires little special skill.

If the backing is to be removed the letter r is placed in the backing symbol.

The use of ceramic backing strips enables welding to be carried out from a single side with full penetration and reduces and often removes the need to grind out and re weld a root from the reverse side.

As with the permanent backing strip care needs to be taken to ensure that the ceramic tile is in close contact with the metal surfaces otherwise slag and or weld metal will run into the gap giving an irregular weld root.

Create a better managed and better suited ceramic manufacturing project by beginning with the proper welding materials.

Esab refrac t back flat 1 x 1 x 1 4 non metallic ceramic 350r weld backing.

Find quality ceramic weld backing for adhesion on all your welding implementations.

The cost savings potential makes this an attractive alternative to arc gouging and rewelding full penetration welds.

Protecting and shaping the weld bead by providing a permanently attached strip of material similar to that being welded is popular see fig 2.

The backing may be either left on the finished cofferdam or void space closing welds without both sides accessibility weld or removed following welding ceramic backing copper strips.