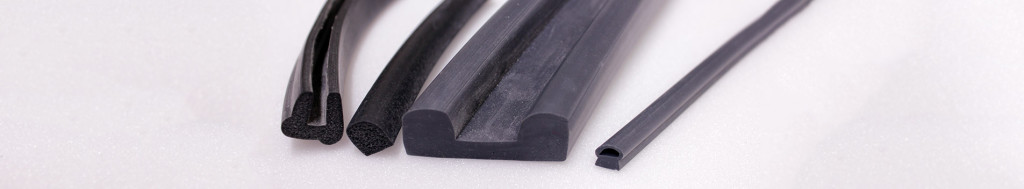

Our extrusions are manufactured in both solid and sponge form in materials such as silicone neoprene epdm nitrile and viton and can be supplied in coil form cut to length or even fabricated bonded to.

Cb frost rubber.

44 0 121 773 8494 menu.

Cb frost produce vast amounts of sponge foam or rubber strip tape every year and cater for small medium and large runs.

Cb frost have been preferred convertors of the rogers corporation.

Cb frost approached us in need of both strategic marketing support and newly designed marketing collateral.

Both techniques are extremely popular due to their efficiency and the frequently fast lead.

The key differences between extrusion and injection moulding.

Cb frost rubber and plastics friday 29 may 2015.

Whilst over 100 years experience in the rubber and plastics industry is impressive we don t stop there.

Continual improvement in training material development equipment and processes together with the dedication of our staff ensures we remain leaders in our market.

Our machinery allows us to produce small intricate gaskets to larger more complex.

Cb frost offer custom made extrusions from a range of polymers each with a unique quality and therefore suited for specific applications.

In the industrial sector injection moulding and extrusion are frequently used techniques for creating products with set shapes and sizes.

Cb frost are specialist manufacturers of a wide range of rubber and plastic materials and products which are suitable for a number of different industries.

Sponge and rubber gaskets cb frost are continually investing in modern production processes to offer a faster turn around and competitive prices.

Weekly strategic marketing meetings at the cb frost offices were arranged to keep all marketing focused and on track and to ensure that we were working as an.